Fascination About Inventory Management

Table of ContentsThe Facts About Inventory Management UncoveredInventory Management Things To Know Before You Get ThisSome Known Factual Statements About Inventory Management The Inventory Management Ideas

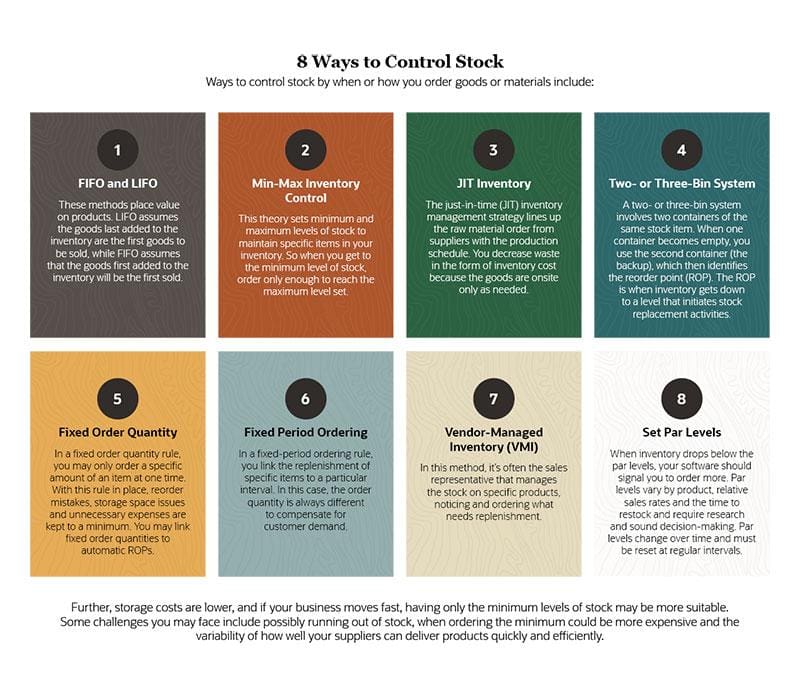

There are two primary approaches of tracking supply: regular and continuous. The main distinction in between these is exactly how frequently data is updated. No matter just how frequently you track supply, you may wish to make use of among the complying with inventory management strategies: ABC Evaluation, ABC (Always Better Control) Analysis is supply management that divides different products right into 3 categories based on pricing as well as is divided into groups A, B, or C.EOQ Model, Economic Order Quantity is a strategy used for planning and also getting an order quantity. It includes making a decision relating to the amount of supply that need to be positioned in supply at any type of provided time.

FSN Method, This method of stock control refers to the process of keeping an eye on all the items of inventory that are not made use of frequently or are not required regularly. They are after that classified right into 3 different groups: fast-moving supply, slow-moving stock, as well as non-moving supply. JIT Method, In the nick of time stock control is a procedure used by suppliers to control their inventory levels.

Some Known Incorrect Statements About Inventory Management

VED Analysis, VED is a strategy used by companies to regulate their inventory. It primarily relates to the management of essential and also preferable extra parts. The high level of inventory that is required for manufacturing typically justifies the low stock for those parts. Among one of the most important variables that a firm need to think about is the accuracy of the information offered in its inventory databases.

Wrike's product launch automation aids speed up product launches with a structured method.

Some Known Incorrect Statements About Inventory Management

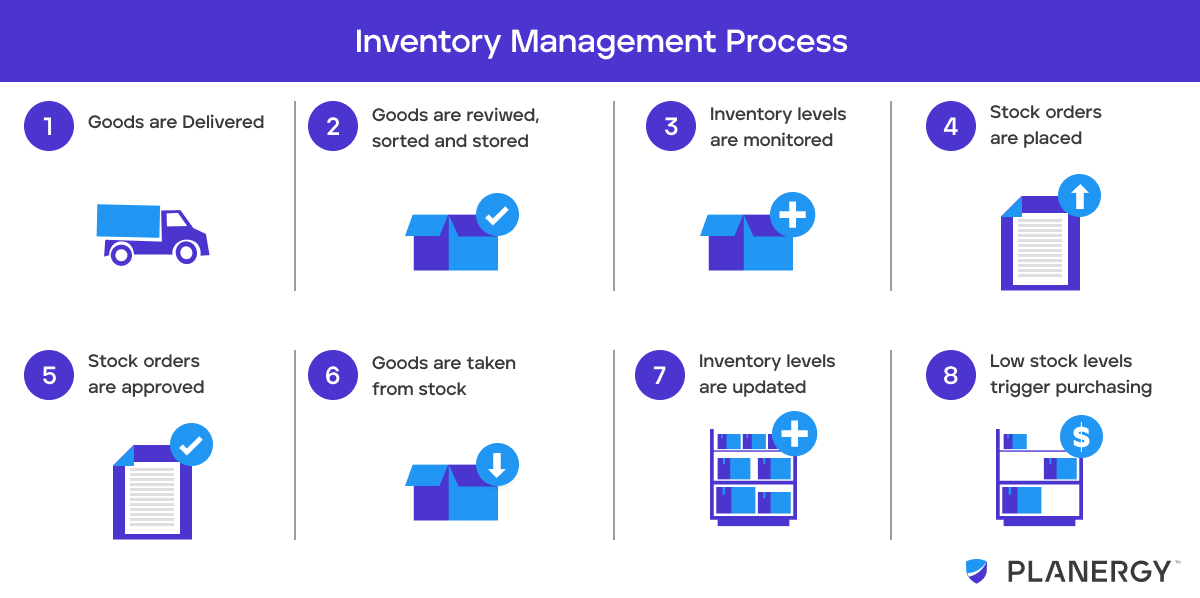

Stock administration refers to the process of buying, keeping, utilizing, and marketing a firm's supply. This includes the management of raw products, parts, as well as completed products, along with warehousing and also processing of such things. There are various types of inventory monitoring, each with its pros and cons, depending on a company's demands.

Supply management tries to efficiently streamline inventories to prevent both excess and scarcities. 4 significant stock monitoring methods consist of just-in-time management (JIT), materials demand planning (MRP), financial order quantity (EOQ), as well as days sales of supply (DSI).

A scarcity of inventory when and also where it's needed can be extremely harmful (Inventory Management). At the exact same time, inventory can be considered a liability (otherwise in an accountancy feeling). A large inventory brings the danger of perishing, burglary, damages, or shifts popular. Supply has to be guaranteed, and also if it is not marketed in time it might have home to be taken care of at clearance pricesor merely destroyed.

Small services will typically keep track of supply manually and also establish the reorder points and also amounts using spread sheet (Excel) formulas.

The Buzz on Inventory Management

Appropriate stock monitoring methods vary relying on the industry. An oil depot is able to save huge quantities of inventory for extended periods of time, permitting it to wait for need to get. While saving oil is pricey and riskya fire in the U.K. in 2005 caused millions of extra pounds in damages and also finesthere is no risk that the inventory will ruin or go out of design.

For firms with complex supply chains and also manufacturing processes, balancing the dangers of stock excess and lacks is specifically difficult. To achieve these balances, companies have actually created numerous methods for inventory administration, consisting of just-in-time (JIT) and also products need preparation (MRP). Some companies, such as monetary services firms, do not have physical stock as well as so needs to count on solution procedure monitoring.

Supply has to be physically counted or gauged prior to it can be put on an equilibrium sheet. Finished products are finished products easily offered for sale to a company's clients. Depending on the kind of service or product being evaluated, a business will certainly utilize various supply management approaches.